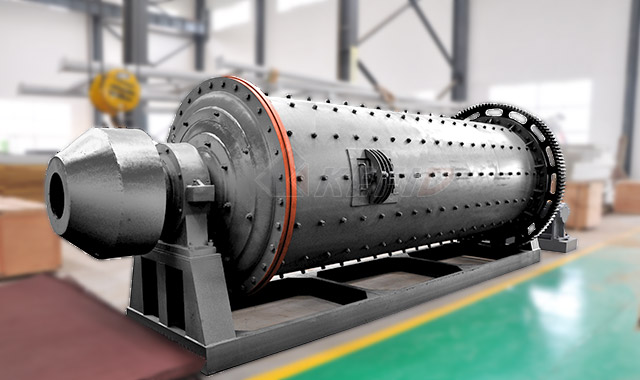

Kefid ball mainly includes the inlet part, outlet part, revolved part ,drying part(reducer, drive gear, engine , control panel). The main body of the grinding chamber adopts the welded frame and the liner is replaced.The revolved gear adopts the welded technique, and there are abrasion liners, which have good performance. Kefid ball mill has a stable operation and reliable performance.

Processed Materials:

various ores and other materials with dry type and wet type, etc.

Applications:

cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc.

| Model | Size of feed opening (mm) | size of outputting feed (mm) | Production (t/h) |

| Ф900×1800 | ≤20 | 0.075-0.89 | 0.65-2 |

| Ф900×3000 | ≤20 | 0.075-0.89 | 1.1-3.5 |

| Ф1200×2400 | ≤25 | 0.075-0.6 | 1.5-4.8 |

| Ф1200×3000 | ≤25 | 0.075-0.4 | 1.6-5 |

| Ф1200×4500 | ≤25 | 0.075-0.4 | 1.6-5.8 |

| Ф1500×3000 | ≤25 | 0.075-0.4 | 2-5 |

| Ф1500×4500 | ≤25 | 0.075-0.4 | 3-6 |

| Ф1500×5700 | ≤25 | 0.075-0.4 | 3.5-6 |

| Ф1830×3000 | ≤25 | 0.075-0.4 | 4-10 |

| Ф1830×6400 | ≤25 | 0.075-0.4 | 6.5-15 |

| Ф1830×7000 | ≤25 | 0.075-0.4 | 7.5-17 |

| Ф2200×5500 | ≤25 | 0.075-0.4 | 10-22 |

| Ф2200×6500 | ≤25 | 0.075-0.4 | 14-26 |

| Ф2200×7500 | ≤25 | 0.075-0.4 | 16-29 |

| Φ2200×9500 | ≤25 | 0.074-0.4 | 18-35 |

Features:

Advantages of the ball mills are lower investment energy saving structure novelty easy and safe to operate stable and reliable performance etc. It is suitable for milling of general and special ore materials.